.png.png)

The Centramate™ 500 S benchtop tangential flow filtration system provides biotechnology and biopharmaceutical drug developers & manufacturers with an ultra-compact portable unit for process development in ultrafiltration (UF) and microfiltration (MF) applications.

Designed for all applications requiring concentration and diafiltration of suspended micro-particulates (such as cell suspensions and lysates) or dissolved solutes (such as proteins or nucleic acids), the sanitary, self-venting, fully drainable design meets the demands of cGMP environments, with full traceability of process-wetted materials. Using the Centramate 500 S system for process development, time, risk, and process volumes are all minimized.

| Pressure Range | 0 to 6 barg (0 to 87 psig) |

| Temperature Range | 0° C to +45° C (32° F to 113° F) |

| Flow Rate | 15 - 600 L/hr |

| Maximum Working Volume | 5 liter (nominal) |

| Minimum Working Volume | 170 mL |

| Cassette Holder Type | Centramate |

| Cassette Holder Area | 0.1 - 0.5 m² membrane area |

| Vessel | 5 L Borosilicate Glass |

| Recirculation | 600 L/hr |

| Diaphragm | Santoprene |

| Flow | 600 L/hr |

| Chemical Seal Capacity | -1 to +6 bar |

| Gaskets | EPDM |

| Inlet/Outlet tubing | Silicon |

| Frame | Stainless Steel 304 |

| Cabinet | Stainless Steel 304 |

The Centramate LV holder is fabricated from Stainless Steel (316L) with female luer fittings for use with 0.01 m2 (0.1 ft2) and 0.02 m2 (0.2 ft2) Centramate cassettes. The holder can accommodate up to 0.04 m2 (0.4 ft2) of screen channel or 0.02 m2 (0.2 ft2) of open channel Centramate cassettes at recommended cross flow rates. A range of luer fittings and valves are available as well as pressure gauges or transducers to set-up a complete TFF system.

| Feed and retentate ports | Female luer SS |

| Filtrate ports | Female luer SS |

| Maximum membrane area | 0.04 m2 (0.4 ft2 |

| Suspended screen | 0.02 m2 (0.2 ft2) |

| Nominal dimensions (Width x Length x Depth) | 12 x 23 6.6 cm (4½ x 9 x 2½ in.) |

| Weight | 4 kg (8.75 lbs) |

| Maximum operating temperature | 50 °C |

| Maximum operating pressure | 5 bar (75 psi) |

The Centramate PE holder has a polyethylene manifold with ¼ in. NPT threaded ports sandwiched between 304 stainless steel outer plates for support. It accommodates up to 4 screen channel (3 suspended screen channel) 0.09 m2 (1 ft2) cassettes. The use of spacers on the tie rods makes it easy to apply and tighten the nuts with minimal threading if only one cassette is installed. As additional cassettes are added, spacers can be removed. The Centramate PE holder is recommended for use in applications where metal contact must be avoided. A plastic, NPT threaded fitting kit, with either 2 or 3 pressure gauges is available.

| Feed and retentate ports | ¼ in. NPT Fitting (female) |

| Filtrate ports | ¼ in. NPT Fitting (female) |

| Screen | 0.37 m2 (4 ft2) |

| Suspended screen | 0.28 m2 (3 ft2) |

| Nominal dimensions (Width x Length x Depth) | 9.4 x 24 x 19 cm (3¾ x 9¼ x 7½ in.) |

| Weight | 8.6 kg (19 lbs) |

| Maximum operating temperature | 80 °C |

| Maximum operating pressure | 6 bar (90 psi) |

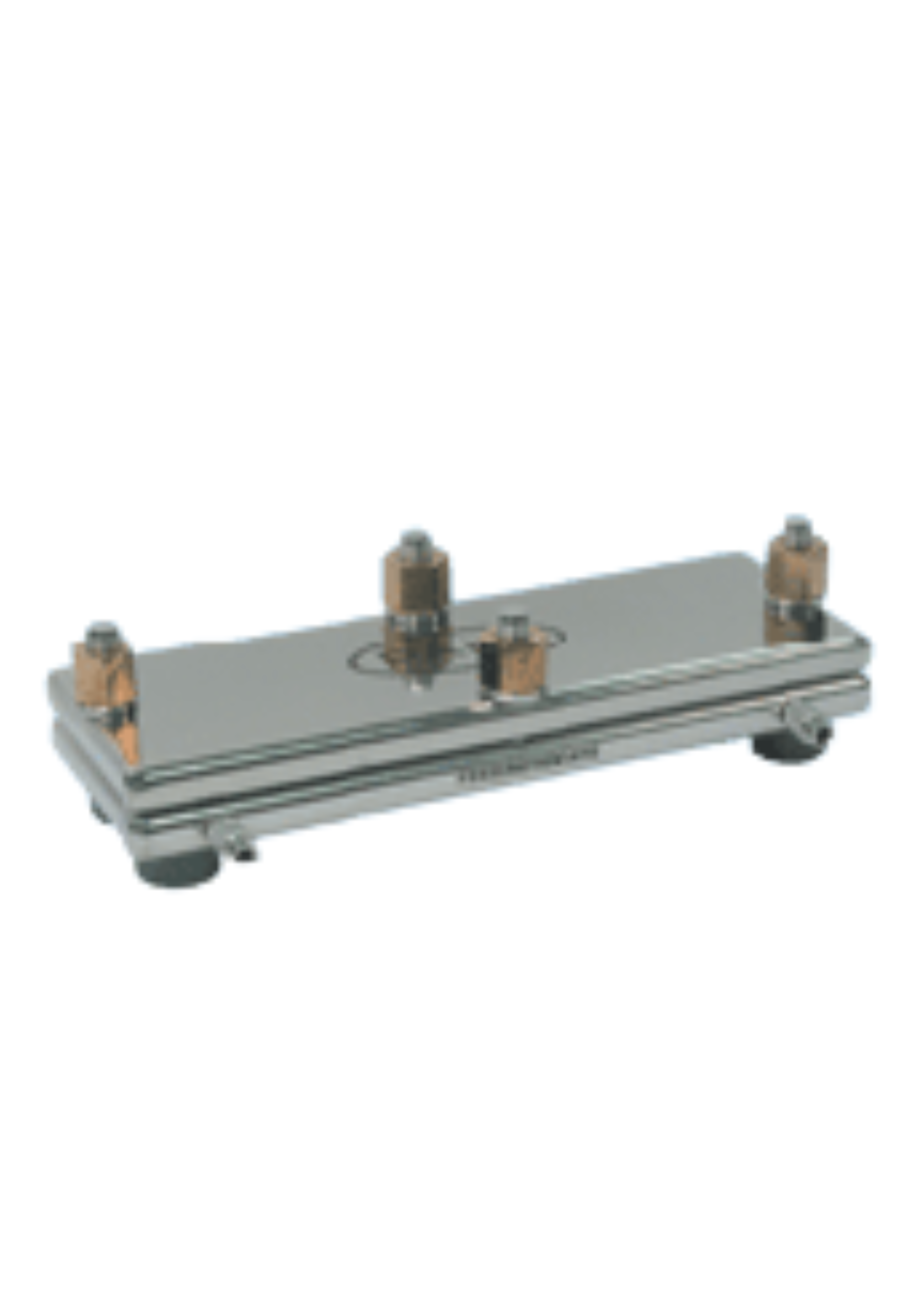

The Centramate stainless steel cassette holder (316L) comes with ½ in. sanitary flanges on feed and filtrate ports. The holder is supplied with surface and weld certification. Up to 5 screen channel (4 suspended screen channel) 0.09 m2 (1 ft2) cassettes can be accommodated. Holder is supplied with both 1 in. and 2 in. spacers on the tie rods to simplify cassette installation and to apply the required torque. Spacers can be removed to compensate for the height difference as additional cassettes are added to the holder. Sanitary fitting kits with either 2 or 3 pressure gauges are available.

| Feed and retentate ports | ½ in. sanitary, 9.6 mm (0.38 in.) bore |

| Filtrate ports | ½ in. sanitary, 8.1 mm (0.32 in.) bore |

| Screen | 0.46 m2 (5 ft2) |

| Suspended screen | 0.37 m2 (4 ft2) |

| Nominal dimensions (Width x Length x Depth) | 13 x 23 x 16 cm (5¼ x 9 x 6¼ in.) |

| Weight | 6.4 kg (14 lbs) |

| Maximum operating temperature | 80 °C |

| Maximum operating pressure | 6 bar (90 psi) |

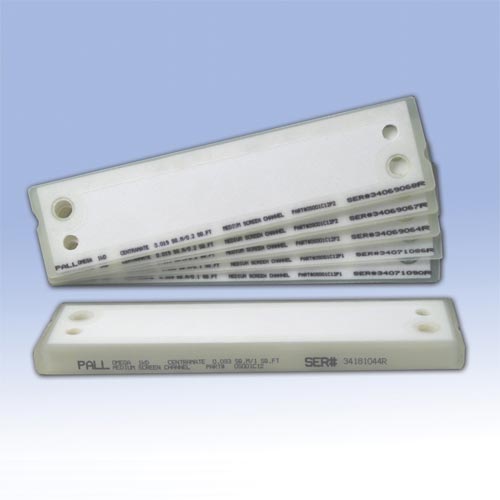

Centramate suspended-screen cassettes with Omega membrane are perfect for laboratory scale and development applications in TFF. The cassettes are supplied with the same construction materials as used in the Centrasette membrane cassettes.

Centramate suspended-screen ultrafiltration cassettes with Omega membrane are perfect for laboratory scale and development applications in TFF. The cassettes are supplied with the same construction materials as used in the Centrasette membrane cassettes.

Applications developed on a Centramate suspended-screen ultrafiltration cassette with Omega membrane can be easily scaled up by adding cassettes to a Centramate holder or switching to the Centrasette cassette format with identical path length and channel format.

| Membrane | Omega low protein-binding modified polyethersulfone |

| Encapsulant | Polyurethane |

| Screens | Polyester |

| Spacers | Polyolefin/PES |

| Nominal Area | 0.01 m2 (0.1 ft2) / 0.02 m2 (0.2 ft2) / 0.1 m2 (1.0 ft2) |

Pall's Omega polyethersulfone (PES) membranes offer high flux and selectivities. They have been specifically modified to minimize protein binding to the surface and interstitial structure of the membrane. This polymeric membrane is stable against biological and physical degradation due to the unique chemical properties of PES.

Omega membranes are cast on a highly porous, non-woven polyolefin support. They have an anisotropic structure, a thin skin-like top layer with a highly porous underlying support. The structure of the skin determines the porosity and permeability characteristics of the membrane and can typically be cleaned quicker and easier than membranes with a uniform, sub-micron depth structure. This membrane is compatible with acids, bases and a variety of other cleaning agents. Omega membranes are available in a wide range of nominal molecular weight cutoffs (NMWC).

| Membrane | Omega polyethersulfone |

| Support | Polyolefin |

| Screens | Polypropylene |

| Encapsulent | Polyurethane with white pigment (TiO2) |

| Permeate Seals | Platinum cured silicone |

| Gaskets | Medical grade, platinum cured silicone |

| Maximum Pressure | 6 barg (90 psig) @ 23 °C 4 barg (60 psig) @ 55 °C |

| Maximum TMP | 4 barg (60 psig) @ 55 °C |

| Temperature Range | -5 – 55 °C |

| pH Range | 2 – 14 |

| Cross Flow Rate for Processing | 5 – 7 L/min/m2 (0.5 – 0.7 L/min/ft2) |

| Cross Flow Rate for Cleaning | 8 – 10 L/min/m2 (0.8 – 1.0 L/min/ft2) |

Delta regenerated cellulose membrane offers high flux and selectivity. The cellulose membrane cassette has been specifically developed to minimize protein binding to the surface and interstitial structure of the membrane. Inherently hydrophilic, this membrane shows low protein adsorption properties and is optimal for processes involving very hydrophilic proteins. Delta regenerated cellulose membrane shows low fouling characteristics, allowing a constant performance or flux during a production run. It is easy to clean and typically recovers normalized water permeability (NWP) by using only 0.8N saline solution.

| Membrane | Delta regenerated cellulose |

| Support | Polypropylene |

| Screens | Polypropylene |

| Encapsulent | Polyurethane with white pigment (TiO2) |

| Permeate Seals | Medical grade, platinum cured silicone |

| Gaskets | Medical grade, platinum cured silicone |

| Maximum Pressure1 | 6 barg (90 psig) @ 23 °C 4 barg (60 psig) @ 55 °C |

| Maximum TMP | 4 barg (60 psig) @ 55 °C |

| Temperature Range | 4 – 55 °C |

| pH Range | 2 – 13 |

| Cross Flow Rate for Processing | 5 – 7 L/min/m2 (0.5 – 0.7 L/min/ft2) |

| Cross Flow Rate for Cleaning | 5 – 8 L/min/m2 (0.5 – 0.8 L/min/ft2) |

Centramate microfiltration cassettes with Supor membrane are perfect for laboratory scale and development TFF applications. The cassettes are available in a range of channel formats to meet most application requirements. The cassettes are supplied with the same construction materials as used in the Centrasette membrane cassettes.

Applications developed on a Centramate cassette with Supor membrane can be easily scaled up by adding cassettes to a Centramate holder or by switching to the Centrasette cassette format with identical path length and channel format.

| Membrane | Supor microfiltration-optimized polyethersulfone |

| Encapsulant | Polyurethane |

| Screens | Polyester |

| Spacers | Polyolefin/PES |

| Nominal Area | 0.01 m2 (0.1 ft2) / 0.02 m2 (0.2 ft2) / 0.1 m2 (1.0 ft2) |